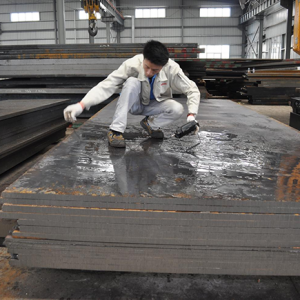

AISI P20 Steel Round Bar Sheet Plate, DIN 1.2311, SCM4

P20 steel round bar sheet plate has many excellent properties. In the pre-hardened status, the mold can be processed without any heat treatment. Which cut down the running period and improves efficiency. After it has been processed through the forged, 1.2311 steel becomes dense. Then it can pass 100% ultrasonic test. And after the test, there will be no pores left and no defect. And it also is called DIN 1.2311 and SCM4 steel. P20 tool steel chemical composition and more information as below

P20 steel round bar sheet plate has many excellent properties. In the pre-hardened status, the mold can be processed without any heat treatment. Which cut down the running period and improves efficiency. After it has been processed through the forged, 1.2311 steel becomes dense. Then it can pass 100% ultrasonic test. And after the test, there will be no pores left and no defect. And it also is called DIN 1.2311 and SCM4 steel. P20 tool steel chemical composition and more information as below

| C | Si | Mn | P | S | Cr | Mo |

| 0.3 – 0.4 | 0.3 – 0.7 | 0.6 – 1 | max 0.03 | max 0.03 | 1.5 – 2 | 0.35 – 0.55 |

P20 Steel Grade Equivalent Chart

| Country | USA | Germany/UK/France | ISO |

|---|---|---|---|

| Standard | ASTM A681-08 Alloy Tool Steel | EN ISO 4957: 1999 Tool Steel | ISO 4957: 1999 Tool Steel |

| Grades | P20 | 35CrMo7/1.2311 | 35CrMo7 |

| Delivery condition: pre-hardened (28-34HRC) with black or bright surface. | Quality control: 100% UT (Ultrasonic Testing), UT Standard is SEP 1921-84 C/c. | ||

| ReH | Minimum yield strength / Mindestwert der oberen Streckgrenze / Limite d elasticite minimale |

| Rm | Tensile strength / Zugfestigkeit / Resistance a la traction |

| A | Minimum elongation / Mindestwert der Bruchdehnung / Allongement minimal |

| J | Notch impact test / Kerbschlagbiegeversuch / Essai de flexion par choc |

|

|

User Reviews

Be the first to review “AISI P20 Steel Round Bar Sheet Plate, DIN 1.2311, SCM4”

There are no reviews yet.