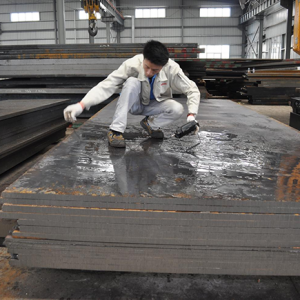

1.2312 Steel Round Bar Sheet Plate Material

1.2312 steel material is a great plastic mold steel in the industry. 1.2312 (40CrMnMoS8-6) belongs to the stand of alloy tool steel of DIN. And many people also call it as 2312 steel. It’s polishing property and machinability are good. And the hardness of everywhere is average with high wear resistance. DIN 1.2312 steel material usually be used in the blowing mould, structural parts, forming tools, injection mold due to the good hardness, high-temperature strength and mechanical property.

Supply Range of 1.2312 Material

Round Bar: diameter 20mm – 500mm

Steel Plate and Steel Block: thickness 12-300mm x width 200-2300mm (*20-120mm plate in stock in prehardened condition)

Surface Finish: Black Surface, Roughly Machined, Peeled & Turned or as per given requirements.

Relevant DIN 1.2312 Steel Specification and Equivalent Steel Grades

| Country | German | USA |

| Standard | DIN EN ISO 4957 | ASTM/AISI |

| Grades | 1.2312 | P20+S |

DIN 1.2312 Material Chemical Composition and Equivalent

| DIN ISO 4957 | C | Mn | P | S | Si | Cr | Mo | |||||

| 1.2312 | 0.35 | 0.45 | 1.30 | 1.60 | 0.03 | 0.05-0.1 | 0.20 | 0.40 | 1.80 | 2.10 | 0.15 | 0.25 |

| ASTM A681 | C | Mn | P | S | Si | Cr | T | |||||

| P20+S | 0.28 | 0.40 | 0.60 | 1.00 | 0.03 | 0.03 | 0.20 | 0.80 | 1.40 | 2.00 | 0.30 | 0.55 |

DIN 1.2312 Plastic Mold Steel Properties

- Density: 7.84 g/cm3

- Linear expansion coefficient: 12.4 *10-6m/(m*K)

- Thermal conductivity: 34 W/(m*K)

- Hardness (in soft annealed condition): < 235 HB

- Hardness (in hardened and tempered condition): < 51 HRC

Forging of 2312

Hot forming temperature: 1100-850 °C.

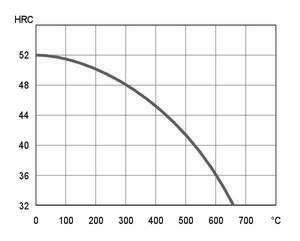

Heat Treatment of Plastic Mold Steel 1.2312

- Grade: 40CrMnMoS8-6

- Material No. W-Nr.: 1.2312

- Hot working temperature / C: 1050 ~ 850

- Annealing temperature / C: 780 ~ 760

- After annealing, the hardness is less than or equal to 230 HBS

- Quenching temperature / C: 830 ~ 870

- Cooling medium: Oil

- Common tempering temperature / C: 640 ~ 680

- Hardness after tempering HRC|100 C: 51

- Hardness after tempering HRC|200 C: 50

- Hardness after tempering HRC|300 C: 48

- Hardness after tempering HRC|400 C: 45

Applications of 1.2312 Materials

DIN 1.2312 is good for plastic injection moulds for thermoplastics, extrusion dies for thermoplastic, compression molds application. Tools for plastics processing and moulds for pressure die casting.

Contact us for further information or the best cost or price of your request.

DIN 1.2312 Plastic Mold Steel Properties

- Density: 7.84 g/cm3

- Linear expansion coefficient: 12.4 *10-6m/(m*K)

- Thermal conductivity: 34 W/(m*K)

- Hardness (in soft annealed condition): < 235 HB

- Hardness (in hardened and tempered condition): < 51 HRC

Forging of 2312

Hot forming temperature: 1100-850 °C.Heat Treatment of Plastic Mold Steel 1.2312

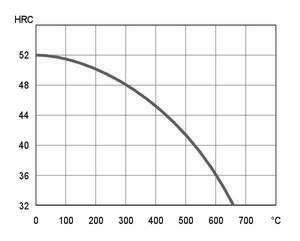

- Grade: 40CrMnMoS8-6

- Material No. W-Nr.: 1.2312

- Hot working temperature / C: 1050 ~ 850

- Annealing temperature / C: 780 ~ 760

- After annealing, the hardness is less than or equal to 230 HBS

- Quenching temperature / C: 830 ~ 870

- Cooling medium: Oil

- Common tempering temperature / C: 640 ~ 680

- Hardness after tempering HRC|100 C: 51

- Hardness after tempering HRC|200 C: 50

- Hardness after tempering HRC|300 C: 48

- Hardness after tempering HRC|400 C: 45

User Reviews

Be the first to review “1.2312 Steel Round Bar Sheet Plate Material”

There are no reviews yet.