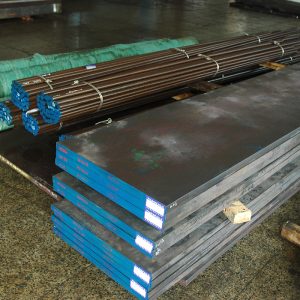

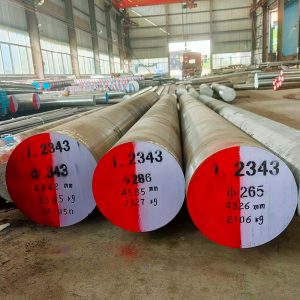

1.2714 55NiCrMoV7 L6 Steel Material Round Bar Sheet Plate

DIN 1.2714 mold steel was made at the base of DIN 1.2344 mould steel. So it has the advantages of 1.2344 steel and has better properties. It has good toughness and malleability. And it also is added the chromium to improve the toughness and fatigue resistance of the 2714 steel material. The Cr content of it is quite high, so it has great hardenability. And air cooling in the time of quenching will get the martensite structure. But its carbon content is on the medium level to make sure to get good hardness after the quenching and tempering. Meanwhile, 1.2714 steel will get good thermostability and high impact toughness. It will get secondary hardening in the high-temperature tempering, then its wearing resistance, corrosion resistance and thermal fatigue resistance will get improve.

DIN 1.2714 mold steel was made at the base of DIN 1.2344 mould steel. So it has the advantages of 1.2344 steel and has better properties. It has good toughness and malleability. And it also is added the chromium to improve the toughness and fatigue resistance of the 2714 steel material. The Cr content of it is quite high, so it has great hardenability. And air cooling in the time of quenching will get the martensite structure. But its carbon content is on the medium level to make sure to get good hardness after the quenching and tempering. Meanwhile, 1.2714 steel will get good thermostability and high impact toughness. It will get secondary hardening in the high-temperature tempering, then its wearing resistance, corrosion resistance and thermal fatigue resistance will get improve.

Chemical Composition

The chemical composition of L6 tool steels is outlined in the following table.

| Element | Content (%) |

|---|---|

| Carbon, C | 0.65-0.75 |

| Manganese, Mn | 0.25-0.80 |

| Silicon, Si | 0.50 |

| Cromium, Cr | 0.60-1.20 |

| Nickel, Ni | 1.25-2.00 |

| Molybdenum, Mo | 0.50 |

| Vanadium, V | 0.20-0.30(a) |

| Copper, Cu | 0.25 |

| Phosphorus, P | 0.03 |

| Sulpher, S | 0.03 |

| Iron, Fe | Balance |

2714 Steel Grade Equivalent

| Country | CHINA | USA | JAPAN | GERMANY/UK/France | ISO |

|---|---|---|---|---|---|

| Standard | GB/T 1299-2000 | ASTM A681-08 | JIS G4404-2006 | EN ISO 4957-1999 | ISO 4957:1999 |

| Grades | 5CrNiMo (T20103) | L6 (T61206) | SKT4 | 55NiCrMoV7 (1.2714) | 55NiCrMoV7 |

Physical Properties

The following table shows the physical properties of L6 tool steels.| Properties | Metric | Imperial |

|---|---|---|

| Melting point | 2590°F | 1421°C |

| Density | 7.86 g/cc | 0.284 lb/in3 |

Mechanical Properties

The mechanical properties of L6 tool steels are displayed in the following table.| Properties | Metric | Imperial |

|---|---|---|

| Poisson's ratio | 0.27-0.30 | 0.27-0.30 |

| Elastic modulus | 190-210 GPa | 27557-30457 ksi |

User Reviews

Be the first to review “1.2714 55NiCrMoV7 L6 Steel Material Round Bar Sheet Plate”

There are no reviews yet.