Tool Steel

Showing all 10 results

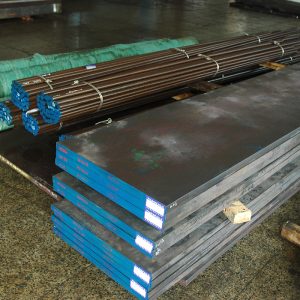

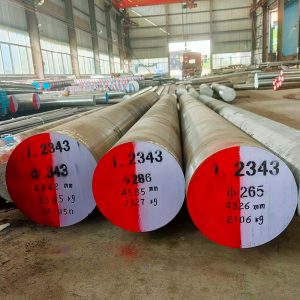

Tool steels are a family carbon and alloy steels having distinct characteristics such as hardness, wear resistance, toughness, and resistance to softening at elevated temperatures.

Tool steels comprise carbide-forming elements such as chromium, vanadium, molybdenum and tungsten in different combinations. They also contain cobalt or nickel which improves their high-temperature performance. They are generally heat-treated to improve the hardness and used for stamping, forming, shearing and cutting metals and forming of plastics. They are classified according to their composition and properties into various categories.

Classifications

Tools steels fall into three basic categories:

- Cold work tool steels

- Hot work tool steels

- High-speed tool steels

Cold-work steels are further subdivided into:

- Air-hardening

- Medium-alloy cold-work steels

- High-carbon, high-chromium cold-work steels

- Oil-hardening cold-work steels

Hot work steels are subdivided into:

- Chromium

- Tungsten

- Molybdenum hot work steels

High-speed tool steels are divided into:

- Molybdenum

- Tungsten

- Intermediate high-speed steels

Other types of tool steels include:

- Water-hardening tool steels

- Shock-resistant tool steels

- Low-carbon tool steels

- Low-alloy special purpose tool steels.

The following table shows the composition limits of various types of tool steels.

| Designation | Compositiona, % | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| AISI | UNS | C | Mn | Si | Cr | Ni | Mo | W | V | Co |

| Molybdenum high-speed steels | ||||||||||

| M1 | T11301 | 0.78-0.88 | 0.15-0.40 | 0.20-0.50 | 3.50-4.00 | 0.30 max | 8.20-9.20 | 1.40-2.10 | 1.00-1.35 | – |

| M2 | T11302 | 0.78-0.88; 0.95-1.05 | 0.15-0.40 | 0.20-0.45 | 3.75-4.50 | 0.30 max | 4.50-5.50 | 5.50-6.75 | 1.75-2.20 | – |

| M3, class 1 | T11313 | 1.00-1.10 | 0.15-0.40 | 0.20-0.45 | 3.75-4.50 | 0.30 max | 4.75-6.50 | 5.00-6.75 | 2.25-2.75 | – |

| M3, class 2 | T11323 | 1.15-1.25 | 0.15-0.40 | 0.20-0.45 | 3.75-4.50 | 0.30 max | 4.75-6.50 | 5.00-6.75 | 2.75-3.75 | – |

| M4 | T11304 | 1.25-1.40 | 0.15-0.40 | 0.20-0.45 | 3.75-4.75 | 0.30 max | 4.25-5.50 | 5.25-6.50 | 3.75-4.50 | – |

| M7 | T11307 | 0.97-1.05 | 0.15-0.40 | 0.20-0.55 | 3.50-4.00 | 0.30 max | 8.20-9.20 | 1.40-2.10 | 1.75-2.25 | – |

| M10 | T11310 | 0.84-0.94; 0.95-1.05 | 0.10-0.40 | 0.20-0.45 | 3.75-4.50 | 0.30 max | 7.75-8.50 | – | 1.80-2.20 | – |

| M30 | T11330 | 0.75-0.85 | 0.15-0.40 | 0.20-0.45 | 3.50-4.25 | 0.30 max | 7.75-9.00 | 1.30-2.30 | 1.00-1.40 | 4.50-5.50 |

| M33 | T11333 | 0.85-0.92 | 0.15-0.40 | 0.15-0.50 | 3.50-4.00 | 0.30 max | 9.00-10.00 | 1.30-2.10 | 1.00-1.35 | 7.75-8.75 |

| M34 | T11334 | 0.85-0.92 | 0.15-0.40 | 0.20-0.45 | 3.50-4.00 | 0.30 max | 7.75-9.20 | 1.40-2.10 | 1.90-2.30 | 7.75-8.75 |

| M35 | T11335 | 0.82-0.88 | 0.15-0.40 | 0.20-0.45 | 3.75-4.50 | 0.30 max | 4.50-5.50 | 5.50-6.75 | 1.75-2.20 | 4.50-5.50 |

| M36 | T11336 | 0.80-0.90 | 0.15-0.40 | 0.20-0.45 | 3.75-4.50 | 0.30 max | 4.58-5.50 | 5.50-6.50 | 1.75-2.25 | 7.75-8.75 |

| M41 | T11341 | 1.05-1.15 | 0.20-0.60 | 0.15-0.50 | 3.75-4.50 | 0.30 max | 3.25-4.25 | 6.25-7.00 | 1.75-2.25 | 4.75-5.75 |

| M42 | T11342 | 1.05-1.15 | 0.15-0.40 | 0.15-0.65 | 3.50-4.25 | 0.30 max | 9.00-10.00 | 1.15-1.85 | 0.95-1.35 | 7.75-8.75 |

| M43 | T11343 | 1.15-1.25 | 0.20-0.40 | 0.15-0.65 | 3.50-4.25 | 0.30 max | 7.50-8.50 | 2.25-3.00 | 1.50-1.75 | 7.75-8.75 |

| M44 | T11344 | 1.10-1.20 | 0.20-0.40 | 0.30-0.55 | 4.00-4.75 | 0.30 max | 6.00-7.00 | 5.00-5.75 | 1.85-2.20 | 11.00-12.25 |

| M46 | T11346 | 1.22-1.30 | 0.20-0.40 | 0.40-0.65 | 3.70-4.20 | 0.30 max | 8.00-8.50 | 1.90-2.20 | 3.00-3.30 | 7.80-8.80 |

| M47 | T11347 | 1.05-1.15 | 0.15-0.40 | 0.20-0.45 | 3.50-4.00 | 0.30 max | 9.25-10.00 | 1.30-1.80 | 1.15-1.35 | 4.75-5.25 |

| M47 | T11348 | 1.42-1.52 | 0.15-0.40 | 0.15-0.40 | 3.50-4.00 | 0.30 max | 4.75-5.50 | 9.50-10.50 | 2.75-3.25 | 8.00-10.00 |

| M62 | T11362 | 1.25-1.35 | 0.15-0.40 | 0.15-0.40 | 3.50-4.00 | 0.30 max | 10.00-11.00 | 5.75-6.50 | 1.80-2.10 | – |

| Tungsten high-speed steels | ||||||||||

| T1 | T12001 | 0.65-0.80 | 0.10-0.40 | 0.20-0.40 | 3.75-4.50 | 0.30 max | – | 17.25-18.75 | 0.90-1.30 | – |

| T2 | T12002 | 0.80-0.90 | 0.20-0.40 | 0.20-0.40 | 3.75-4.50 | 0.30 max | 1.0 max | 17.50-19.00 | 1.80-2.40 | – |

| T4 | T12004 | 0.70-0.80 | 0.10-0.40 | 0.20-0.40 | 3.75-4.50 | 0.30 max | 0.40-1.00 | 17.50- 19.00 | 0.80-1.20 | 4.25-5.75 |

| T5 | T12005 | 0.75-0.85 | 0.20-0.40 | 0.20-0.40 | 3.75-5.00 | 0.30 max | 0.50-1.25 | 17.50-19.00 | 1.80- 2.40 | 7.00-9.50 |

| T6 | T12006 | 0.75-0.85 | 0.20-0.40 | 0.20-0.40 | 4.00-4.75 | 0.30 max | 0.40-1.00 | 18.50-21.00 | 1.50- 2.10 | 11.00-13.00 |

| T8 | T12008 | 0.75-0.85 | 0.20-0.40 | 0.20-0.40 | 3.75-4.50 | 0.30 max | 0.40-1.00 | 13.25-14.75 | 1.80- 2.40 | 4.25-5.75 |

| T15 | T12015 | 1.50-1.60 | 0.15-0.40 | 0.15-0.40 | 3.75-5.00 | 0.30 max | 1.00 max | 11.75- 13.00 | 4.50-5.25 | 4.75-5.25 |

| Intermediate high-speed steels | ||||||||||

| M50 | T11350 | 0.78-0.88 | 0.15-0.45 | 0.20-0.60 | 3.75-4.50 | 0.30 max | 3.90-4.75 | – | 0.80- 1.25 | – |

| M52 | T11352 | 0.85-0.95 | 0.15-0.45 | 0.20-0.60 | 3.50-4.30 | 0.30 max | 4.00-4.90 | 0.75-1.50 | 1.65- 2.25 | – |

| Chromium hot-work steels | ||||||||||

| H10 | T20810 | 0.35-0.45 | 0.25-0.70 | 0.80-1.20 | 3.00-3.75 | 0.30 max | 2.00-3.00 | – | 0.25-0.75 | – |

| H11 | T20811 | 0.33-0.43 | 0.20-0.50 | 0.80-1.20 | 4.75-5.50 | 0.30 max | 1.10-1.60 | – | 0.30- 0.60 | – |

| H12 | T20812 | 0.30-0.40 | 0.20-0.50 | 0.80-1.20 | 4.75-5.50 | 0.30 max | 1.25-1.75 | 1.00- 1.70 | 0.50 max | – |

| H13 | T20813 | 0.32-0.45 | 0.20-0.50 | 0.80-1.20 | 4.75-5.50 | 0.30 max | 1.10-1.75 | – | 0.80- 1.20 | – |

| H14 | T20814 | 0.35-0.45 | 0.20-0.50 | 0.80-1.20 | 4.75-5.50 | 0.30 max | – | 4.00- 5.25 | – | – |

| H19 | T20819 | 0.32-0.45 | 0.20-0.50 | 0.20-0.50 | 4.00-4.75 | 0.30 max | 0.30-0.55 | 3.75- 4.50 | 1.75-2.20 | 4.00-4.50 |

| Tungsten hot-work steels | ||||||||||

| H21 | T20821 | 0.28-0.36 | 0.15-0.40 | 0.15-0.50 | 3.00-3.75 | 0.30 max | – | 8.50- 10.00 | 0.30-0.60 | – |

| H22 | T20822 | 0.30-0.40 | 0.15-0.40 | 0.15-0.40 | 1.75-3.75 | 0.30 max | – | 10.00-11.75 | 0.25- 0.50 | – |

| H23 | T20823 | 0.25-0.35 | 0.15-0.40 | 0.15-0.60 | 11.00-12.75 | 0.30 max | – | 11.00-12.75 | 0.75- 1.25 | – |

| H24 | T20824 | 0.42-0.53 | 0.15-0.40 | 0.15-0.40 | 2.50-3.50 | 0.30 max | – | 14.00-16.00 | 0.40- 0.60 | – |

| H25 | T20825 | 0.22-0.32 | 0.15-0.40 | 0.15-0.40 | 3.75-4.50 | 0.30 max | – | 14.00-16.00 | 0.40- 0.60 | – |

| H26 | T20826 | 0.45-0.55b | 0.15-0.40 | 0.15-0.40 | 3.75-4.50 | 0.30 max | – | 17.25- 19.00 | 0.75-1.25 | – |

| Molybdenum hot-work steels | ||||||||||

| H42 | T20842 | 0.55-0.70b | 0.15-0.40 | – | 3.75-4.50 | 0.30 max | 4.50- 5.50 | 5.50-6.75 | 1.75-2.20 | – |

| Air-hardening, medium-alloy, cold-work steels | ||||||||||

| A2 | T30102 | 0.95-1.05 | 1.00 max | 0.50 max | 4.75-5.50 | 0.30 max | 0.90-1.40 | – | 0.15-0.50 | – |

| A3 | T30103 | 1.20-1.30 | 0.40-0.60 | 0.50 max | 4.75-5.50 | 0.30 max | 0.90-1.40 | – | 0.80- 1.40 | – |

| A4 | T30104 | 0.95-1.05 | 1.80-2.20 | 0.50 max | 0.90-2.20 | 0.30 max | 0.90-1.40 | – | – | – |

| A6 | T30106 | 0.65-0.75 | 1.80-2.50 | 0.50 max | 0.90-1.20 | 0.30 max | 0.90-1.40 | – | – | – |

| A7 | T30107 | 2.00-2.85 | 0.80 max | 0.50 max | 5.00-5.75 | 0.30 max | 0.90-1.40 | 0.50- 1.50 | 3.90-5.15 | – |

| A8 | T30108 | 0.50-0.60 | 0.50 max | 0.75-1.10 | 4.75-5.50 | 0.30 max | 1.15-1.65 | 1.00- 1.50 | – | – |

| A9 | T30109 | 0.45-0.55 | 0.50 max | 0.95-1.15 | 4.75-5.50 | 1.25-1.75 | 1.30-1.80 | – | 0.80- 1.40 | – |

| A10 | T30110 | 1.25-1.50c | 1.60-2.10 | 1.00-1.50 | – | 1.55-2.05 | 1.25-1.75 | – | – | – |

| High-carbon, high-chromium, cold-work steels | ||||||||||

| D2 | T30402 | 1.40-1.60 | 0.60 max | 0.60 max | 11.00-13.00 | 0.30 max | 0.70-1.20 | – | 1.10 max | – |

| D3 | T30403 | 2.00-2.35 | 0.60 max | 0.60 max | 11.00-13.50 | 0.30 max | – | 1.00 max | 1.00 max | – |

| D4 | T30404 | 2.05-2.40 | 0.60 max | 0.60 max | 11.00-13.00 | 0.30 max | 0.70-1.20 | – | 1.00 max | – |

| D5 | T30405 | 1.40-1.60 | 0.60 max | 0.60 max | 11.00-13.00 | 0.30 max | 0.70-1.20 | – | 1.00 max | 2.50-3.50 |

| D7 | T30407 | 2.15-2.50 | 0.60 max | 0.60 max | 11.50-13.50 | 0.30 max | 0.70-1.20 | – | 3.80-4.40 | – |

| Oil-hardening cold-work steels | ||||||||||

| O1 | T31501 | 0.85-1.00 | 1.00-1.40 | 0.50 max | 0.40-0.60 | 0.30 max | – | 0.40-0.60 | 0.30 max | – |

| O2 | T31502 | 0.85-0.95 | 1.40-1.80 | 0.50 max | 0.50 max | 0.30 max | 0.30 max | – | 0.30 max | – |

| O6 | T31506 | 1.25-1.55c | 0.30-1.10 | 0.55-1.50 | 0.30 max | 0.30 max | 0.20-0.30 | – | – | – |

| O7 | T31507 | 1.10-1.30 | 1.00 max | 0.60 max | 0.35-0.85 | 0.30 max | 0.30 max | 1.00-2.00 | 0.40 max | – |

| Shock-resisting steels | ||||||||||

| S1 | T41901 | 0.40-0.55 | 0.10-0.40 | 0.15-1.20 | 1.00-1.80 | 0.30 max | 0.50 max | 1.50-3.00 | 0.15-0.30 | – |

| S2 | T41902 | 0.40-0.55 | 0.30-0.50 | 0.90-1.20 | – | 0.30 max | 0.30-0.60 | – | 0.50 max | – |

| S5 | T41905 | 0.50-0.65 | 0.60-1.00 | 1.75-2.25 | 0.50 max | – | 0.20-1.35 | – | 0.35 max | – |

| S6 | T41906 | 0.40-0.50 | 1.20-1.50 | 2.00-2.50 | 1.20-1.50 | – | 0.30-0.50 | – | 0.20-0.40 | – |

| S7 | T41907 | 0.45-0.55 | 0.20-0.90 | 0.20-1.00 | 3.00-3.50 | – | 1.30-1.80 | – | 0.20-0.30d | – |

| Low-alloy special-purpose tool steels | ||||||||||

| L2 | T61202 | 0.45-1.00b | 0.10-0.90 | 0.50 max | 0.70-1.20 | – | 0.25 max | – | 0.10-0.30 | – |

| L6 | T61206 | 0.65-0.75 | 0.25-0.80 | 0.50 max | 0.60-1.20 | 1.25-2.00 | 0.50 max | – | 0.20-0.30d | – |

| Low-carbon mold steels | ||||||||||

| P2 | T51602 | 0.10 max | 0.10-0.40 | 0.10-0.40 | 0.75-1.25 | 0.10-0.50 | 0.15-0.40 | – | – | – |

| P3 | T51603 | 0.10 max | 0.20-0.60 | 0.40 max | 0.40-0.75 | 1.00-1.50 | – | – | – | – |

| P4 | T51604 | 0.12 max | 0.20-0.60 | 0.10-0.40 | 4.00-5.25 | – | 0.40-1.00 | – | – | – |

| P5 | T51605 | 0.10 max | 0.20-0.60 | 0.40 max | 2.00-2.50 | 0.35 max | – | – | – | – |

| P6 | T51606 | 0.05-0.15 | 0.35-0.70 | 0.10-0.40 | 1.25-1.75 | 3.25-3.75 | – | – | – | – |

| P20 | T51620 | 0.28-0.40 | 0.60-1.00 | 0.20-0.80 | 0.40-2.00 | – | 0.30-0.55 | – | – | – |

| P21 | T51621 | 0.18-0.22 | 0.20-0.40 | 0.20-0.40 | 0.50 max | 3.90-4.25 | – | – | 0.15-0.25 | 1.05-1.25A1 |

| Water-hardening tool steels | ||||||||||

| W1 | T72301 | 0.70-1.50e | 0.10-0.40 | 0.10-0.40 | 0.15 max | 0.20 max | 0.10 max | 0.15 max | 0.10 max | – |

| W2 | T72302 | 0.85-1.50e | 0.10-0.40 | 0.10-0.40 | 0.15 max | 0.20 max | 0.10 max | 0.15 max | 0.15-0.35 | – |

| W3 | T72305 | 1.05-1.15 | 0.10-0.40 | 0.10-0.40 | 0.40-0.60 | 0.20 max | 0.10 max | 0.15 max | 0.10 max | – |

aExcept group W, all steels contain 0.03 max S, 0.03 max P and 0.25 max Cu; group W contain 0.025 max S, 0.025 max P, and 0.20 max Cu. As mentioned, amount of sulfur may be increased from 0.06% to 0.15% to enhance the machinability of group A, M, T, H and D steels.

bPresent in various carbon ranges.

cPresence of free graphite in the microstructure.

dOptional.

eSpecified ranges of carbon are indicated using suffix numbers.

In the above table, a capital letter is used to identify each group of tool steels having similar properties and composition; within that group, each type of tool steel is assigned a code number.