Company Profile

Dongguan Songshun Mould Steel Co., Ltd. is located in Chang’an Town – the famous town of mold in Pearl River Delta of China. After 10 years’ development, now we have the capacity to provide complete services from manufacturing and marketing to distributing.

The main grades of tool steel and special steel which we market are listed as follows:

1. Plastic Mould Steel(NAK80/P20+Ni/1.2738/718/P20/1.2311/3Cr2Mo/1.2311/S136/2316)

2. Hot Work Steel/Hardware Mould Steel(8407/Px5/3Cr17NiMo/2711/2316/Px4/H13/4CrMo2WvMn)

3. Cold Work Steel/Hardware Mould Steel (DC53/Cr12/Cr/Cr12mo/Cr12mo1v1/K460/K110/K107/SKD11/D2/YK30/SLD/2510/T/S55C/S50C)

4. Bearing Steel(Gcr15)

5. Stainless Steel(201/202/301/302/304/304L/304LN/304TI/307/316/316H /316TI317 317L/309 330 660 631 632 630)Etc.

As a large-scale wholesaler and retailer, we have the excellent service organization and first-class marketing personnel. We have been specialized in domestic and overseas markets for many years, and have established good and stable business relationships with many overseas clients. Because of our high-quality products, timely delivery, competitive price and good service, we have won high praises from all our customers.We always insist on the idea of “The quality is first, the customer is supreme”, and inherit the principle of “equality, equity and reciprocity”. We sincerely hope to cooperate with more importers, and make progress together.

Customers Review

Mohd Shawish

Everything is good, thank you very much.

Very happy to do business with you and very grateful for all your hard word and help making this partnership so successful.

Thank you

Jonhannes Von Reusner

thank you, really appreciate how Songshun Mould Steel and you personally have helped us here.

Thark you so much for taking the time to quote on different steels, answering all our questions and being so flexible.

We are so lucky to have you as our trusted steel partner in China.

Please send my congratulations to your company for doing such a great job.

Myers Richardson

We have received the 4140 steel bar on time.

Just wanted to write and say a big Thank You for how great it is to work with your company.

Thank you for taking the trouble to help find a new process, including dealing with the bending issues we had.

Very glad with your support and looking forward to buying more and more from you.

Thank you

What we been through?

In 2000, the founder left the hometown to go to Guangdong province. Due to the help of his hometown friend, get the work of the steel industry. He rode a motorcycle and traveled through every street to find customers who really need special steel.

Under the efforts of many years, many resources were integrated. In 2010, one of the steel warehouses reached 8000㎡. And the stock of all grades special steel is reached to about 8000 tons.

As time went on, the local business of special steel grew bigger. The founder sharply captured the business opportunity for foreign trade. And the Ministry of Foreign Trade was established in 2012.

Since then, it becomes the new branch of our company business, the mission is to provide steel and best service for foreign customers.

After almost 20 years of development and growth, Songshun Steel becomes one comprehensive special steel factory, stockist and exporter. The excellent customer group, capital conditions, service attitude and professionalism always push us to get better to service customers.

The great experienced exporting team and professional engineer team as our strong back to make everyone understand what Chinese steel really is.

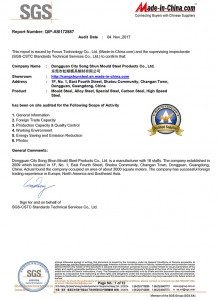

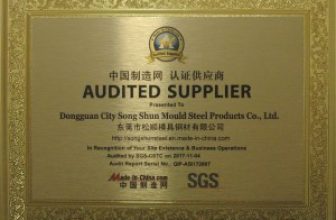

Songshun Steel Certifications

Steel Supply

Steel is one of the most important material in the industry system. It can be used to make fittings or products, even the building. So according to the uses and the production capacity, people should use different steel and quantity of it. Every type of steel has own properties. So some grades steel can be made the blade and some types of steel are good material for the screw.

You maybe feel confused about how to get good steel supplier for any reasons. Such as the local steel company can not perfectly meet your requirements, the steel material at the local market does not exist and etc.

Don’t worry about that, our company can solve this problem for you. Our company is good at international steel supply due to the so many year’s developments. Just tell us your requirements and quantity, even the engineering drawing. We will give you the best solution according to your project. The steel supply catalog of our company as below, please kindly check out to get what you want. If could not find what you want, maybe you can tell us then find out what is going on and take the equivalent grade.

Production and Service

Steel Produce Process

Songshun Steel Co Ltd supplies a wide range of forged, hot rolled, cold rolled, cold drawn and cast steel materials. We have lots of stock materials for fast delivery

Steel Chemical Analysis

It is very important for tool steel and alloy steel that chemical composition analysis. We are equipped with Japan’s Olympus brand spectrometer, XRF Analyzer. We check the chemical composition each heat to ensure the materials is with top quality in chemical composition.

Steel Heat Treat

Steel needs to be heat treated differently because of customers require different steels, chemical compositions, industrial requirements, and so on.

We provide different steel round bar, flat bar, steel plate, steel sheets, steel rods with various heat treatments condition for your industrial uses:Quenching-Q; Normalizing-N; Tempering-T; Annealing-A

Steel Chemical Analysis

It is very important for tool steel and alloy steel that chemical composition analysis. We are equipped with Japan’s Olympus brand spectrometer, XRF Analyzer. We check the chemical composition each heat to ensure the materials is with top quality in chemical composition.

Steel Ultrasonic Test

We would do the Ultrasonic Test before the delivery for all our supplied steel products to guarantee the steel materials quality. The main standard for the UT class is DIN SEP 1921-84. Our materials could meet the UT Class C/c, Class D/d or E/e requirements.

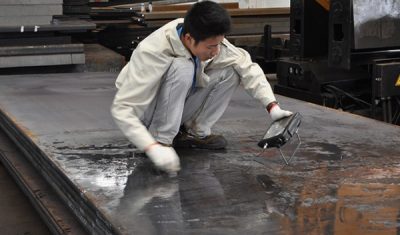

Steel Surface Treatment

We supply tool steel and alloy steel as below surface condition according to your different requirements:(black、roughly peeled、turned、milled、grounded、polishing)

Steel Tolerance Control

We supply tool steel materials and engineering steel according to standard tolerance or customer’s required tolerance. You just need to tell us your detail about the tolerance of your needs.

Standard Delivery and Packing of Steel

For container shipment, standard packing and bundle round bar and flat bar would be applied. It is necessary to fasten & reinforcement would be done to ensure the safety and better unloading at the destination port.

For less than container shipment, wooden box package would be applied for different size materials. For milled or grounded materials, the anti-rust oil would be needed to ensure the surface condition, within the wooden box.

The shipment is 7-10 days If your needs are in stock in our warehouse. If our warehouse is not ready for your needs, we need 30-40 days to work on it. In our factory, the quality is the first pick, we sincerely hope you could understand.

Steel MTC

MTC is available for each shipment after all inspect results are available.

You could get the steel MTC after all inspect results are available.

Service Details:

- Steel Cut Service:

We could supply the service of steel cut, according to your need. This would save your energy and labour cost, we could supply your final required size. - Steel Machining

We supply machined, milled or grounded surface condition for different steel grades. Diameter tolerance and size tolerance would meet ISO standard. - About Drawing

If you have the industry drawing, please send to us and we could supply it, as per the required steel grades and drawing dimension. - Steel Design and Consult

If you know nothing as a trading company or something, but you would need some kind of steel products. Tell us what you need, and we could design and supply to you

| Songshun Steel Supply | ||||||

|---|---|---|---|---|---|---|

| Alloy Steel | ||||||

| GB | ISO | ASTM | JIS | DIN | BS | NF |

| 20Mn2 | 22Mn6 | 1320 1321 1330 1524 | SMn420 | 20Mn5 PH355 | 150M19 | 20M5 |

| 30Mn2 | 28Mn6 | 1330 1536 | SMn433 SMn433H | 28Mn6 30Mn5 34Mn5 | 28Mn6 150M28 | 28Mn6 32M5 |

| 35Mn2 | 36Mn6 | 1335 | SCMn443 SMn438 SMn438H | 36Mn5 | 150M36 | 35M5 |

| 40Mn2 | 42Mn6 | 1340 | SMn438 SMn443 SMn443H | — | — | 40M5 |

| 45Mn2 | 42Mn6 | 1345 | SMn443 | 46Mn7 | — | 45M5 |

| 50Mn2 | — | H13450 | — | 50Mn7 | — | 55M5 |

| 15Cr | — | 5115 | SCr415 | 17Cr3 15Cr3 | 527A17 523M15 | — 12C3 |

| 15CrA | — | 5115 | SCr415 | 17Cr3 | 527A17 | — |

| 20Cr | 20Cr4 | 5120 | SCr420 SCr420H | 20Cr4 | 590M17 527A19 527M20 | 18C3 |

| 30Cr | 34Cr4 | 5130 | SCr430 | 34Cr4 28Cr4 | 34Cr4 530A30 | 34Cr4 |

| 35Cr | Cr4 | 5135 5132 | SCr435 SCr435H | 34Cr4 37Cr4 38Cr2 | 34Cr4 530A32 530A35 | 34Cr4 32C4 38C2 38C4 |

| 40Cr | 41Cr4 | 5140 | SCr440 SCr440H | 41Cr4 | 41Cr4 520M40 530A40 530M40 | 41Cr4 42C4 |

| 45Cr | Cr4 | 5145 5147 | SCr445 | 41Cr4 | 41Cr4 534A99 | 41Cr4 45C4 |

| 50Cr | — | 5150 | SCr445 | — | — | 50C4 |

| 12CrMo | — | A182-F11 F12 | — | 13CrMo44 | 620Cr·B | 12CD4 |

| 15CrMo | — | A-387Cr·B | STC42 STT42 STB42 SCM415 | 13CrMo45 16CrMo44 15CrMo5 | 1653 | 12CD4 15CD4·05 |

| 20CrMo | 18CrMo4 (7) | 4118 | SCM22 STC42 STT42 STB42 | 25CrMo4 20CrMo44 | 25CrMo4 708M20 CDS12 CDS110 | 25CrMo4 18CD4 |

| 30CrMo | 1 2 | 4130 | SCM420 SCM430 | 25CrMo4 | 25CrMO4 1717COS110 | 25CrMo4 25CD4 |

| 12CrMoA | 2 | 4130 | SCM430 | 34CrMo4 | 34CrMo4 | 34CrMo4 |

| 35CrMo | 34CrMo4 | 4137 4135 | SCM435 SCM432 SCCrM3 | 34CrMo4 | 34CrMo4 708A37 | 34CrMo4 35CD4 |

| 42CrMo | 42CrMo4 | 4140 4142 | SCM440 | 42CrMo4 41CrMo4 | 42CrMo4 708M40 | 42CrMo4 42CD4 42CD4TS |

| 38CrMoAI | 41CrAIMo74 | — | SACM645 | 41CrAIMo7 34CrAIMo5 | 905M39 905M31 | 40CAD6.12 30CAD6.12 |

| 50CrVA | 13 | — | SUP10 | 51CrV4 | 51CrV4 735A51 735A50 | 51CrV4 50CV4 |

| 20CrMn | 20MnCr5 | — | SMnC420 | 20MnCr5 | — | 20MC5 |

| 40CrMnMo | 42CrMo4 | 4140 4142 | SCM440 | 42CrMo4 | 42CrMo4 708A42 | 42CrMo4 |

| 40CrNi | — | 3140 | SNC236 | 40NiCr6 | 640M40 | — |

| 12CrNi3 | 15NiCr13 | — | SNC815 | 14NiCr14 | 832H13 655M13 665A12 | 14NC12 |

| 20CrNiMo | 20CrNiMo2 (12) | 8720 | SNCM220 | 21NiCrMo2 | 805M20 | 20NCD2 |

| 40CrNiMoA | — | 4340 | SNCM439 | 40NiCrMo6 36NiCrMo4 | 3S97 3S99 | 40NCD3 |

| Cr2 | 100Cr2 | L1 | — | 100Cr6 | BL1 | 100Cr6 100C6 |

| Cr12 | 210Cr12 | D3 | SKD1 | X210Cr12 | BD3 | Z200C12 |

| Cr12Mo1V1 | 160CrMoV12 | D2 | SKD11 | X155CrV-Mo121 | BD2 | – |

| Cr12MoV | – | D2 | SKD11 | 165CrMoV46 | BD2 | Z200C12 |

| Cr5Mo1V | 100CrMoV5 | A2 | SKD12 | – | BA2 | X100Cr-MoV5 |

| 9Mn2V | 90MnV2 | O2 | — | 90MnV8 | BO2 | 90MnV8 80M80 |

| CrWMn | 105WCr1 | O7 | SKS31 SKS2 SKS3 | 105WCr6 | — | 105WCr5 105WC13 |

| 5CrNiMo | — | L6 | SKT4 | 55NiCrMoV6 | BH224/5 | 55NCDV7 |

| 3Cr2W8V | 30WCrV9 | H21 H10 | SKD5 | X30WCrV93 X32CrMnV33 | BH21 BH10 | X30WCrV9 Z30WCV9 32DCV28 |

| 4Cr5MoSiV | — | H11 H12 | SKD6 SKD62 | X38CrMoV51 X37CrMoW51 | BH11 BH12 | X38CrMoV5 Z38CDV5 Z35CWDV5 |

| 4Cr5MoSiV1 | 40CrMoV5 | H H13 | SKD61 | X40CrMoV51 | BH13 | X40CrMoV5 Z40CDV5 |

| High Speed Steel | ||||||

| W18Cr4V | HS18-0-1 | T1 | SKH2 | S18-0-1B18 | BT1 | HS18-0-1 Z80WCV18-04-01 Z80WCN18-04-01 |

| W18Cr4VCo5 | HS18-1-1-5 | T4 T5 T6 | SKH3 SKH4A SKH4B | S18-1-2-5 S18-1-2-10 S18-1-2-15 | BT4 BT5 BT6 | HS18-1-1-5 Z80WKCV18-05-04-01 Z85WK18-10 |

| W18Cr4V-2Co8 | HS18-0-1-10 | T5 | SKH40 | S18-1-2-10 | BT5 | HS18-0-2-9 Z80WKCV18-05-04-02 |

| W12Cr4V-5Co5 | HS12-1-5-5 | T15 | SKH10 | S12-1-4-5 S12-1-5-5 | BT15 | Z160WK12-05-05-04 HS12-1-5-5 |

| W6Mo5Cr-4V2 | HS6-5-2 | M2 (Regular C) | SKH51 SKH9 | S6-5-2 SC6-5-2 | BM2 | HS6-5-2 Z85WDCV06-05-04-02 Z90WDCV06-05-04-02 |

| CW6Mo5-Cr4V2 | — | M2 (High C) | — | SC6-5-2 | — | — |

| W6Mo5Cr-4V3 | HS6-5-3 | M3 (class a) | SKH52 | S6-5-3 | — | Z12WDCV06-05-04-03 |

| CW6Mo5Cr-4V3 | HS6-5-3 | M3 (class b) | SKH53 | S6-5-3 | — | HS6-5-3 |

| W2Mo9Cr-4V2 | HS2-9-2 | M7 | SKH58 | S2-9-2 | — | HS2-9-2 Z100DCWV09-04-02-02 |

| W6Mo5Cr4-V2Co5 | HS6-5-2-5 | M35 | SKH55 | S6-5-2-5 | — | HS6-5-2-5 Z85WDKCV06-05-05-04-02 |

| W7Mo4Cr4-V2Co5 | HS7-4-2-5 | M41 | — | S7-4-2-5 | — | HS7-4-2-5 Z110WKCDV07-05-04-04-02 |

| W2Mo9Cr-4VCo8 | HS2-9-1-8 | M42 | SKH59 | S2-10-1-8 | BM42 | HS2-9-1-8 Z110WKCDV09-08-04-02-01 |